As the demand for electric vehicles increased in line with the environment-friendly trend, the battery, which is a key component, also entered a high growth trend, but waste batteries were not the target of attention. The image of’used batteries’ also played a part, but due to environmental and safety issues, it was due to regulations requiring unconditional return of batteries when scrapped electric vehicles.

However, with the abolition of related regulations, the waste battery market is showing signs of a significant expansion. The energy storage device (ESS) industry, struggling with a shortage of battery supply and demand, first welcomed with open arms. This is because even a battery that can no longer run is likely to be used as an ESS battery. As soon as safety and efficiency are verified, the automaker industry is expected to be free from environmental problems resulting from the disposal of waste batteries.

Hyundai Motor Group announced on the 10th that it has begun a demonstration project linking electric vehicle batteries and renewable energy with Korea Hydro & Nuclear Power. It is a project to utilize batteries recovered from electric vehicles for renewable energy-linked ESS, and it is highly likely to lead to the promotion of the world’s largest 3 gigawatt hour (GWh)-class waste battery reuse ESS project.

Although it is not worth the old battery loan, the possibility of using ESS is sufficient

If the capacity of the electric vehicle battery decreases by more than 80% compared to the initial period, it becomes a waste battery that is subject to replacement. However, this is only because the value for’electric vehicle batteries’ with high performance standards has fallen, and the possibility of using ESS batteries is sufficient. According to the National Renewable Energy Research Institute (NREL) and the German Renewable Energy Association (BEE), if an electric vehicle battery that has been used for 7 to 8 years is recycled, it can be used for 10 years even at 70 to 80% of its initial capacity.

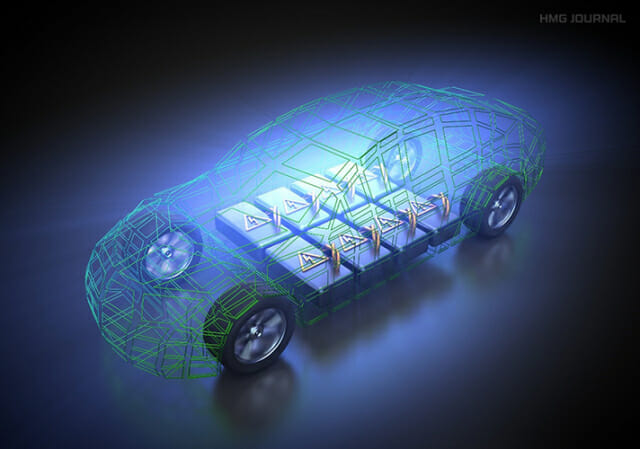

The battery, which is the core of an electric vehicle, is made up of high value-added parts that account for 40% of the vehicle price, so its utilization is endless. Since it is a registered asset, it is easy to recover and secure, and the price of a new battery is lower than that of a new battery.

Above all, the electric vehicle used battery industry is regarded as a niche market that does not have special standards for performance evaluation or reuse, although demand is expected to increase in the future. An industry official said, “The battery pack collected from the electric vehicle is disassembled to diagnose the battery condition.” “After that, it is classified as a battery with the same performance and then reprocessed into an ESS battery tray.”

Contrary to high demand, the search for waste batteries in Korea was picking stars in the sky. In the category of waste prohibited from importation announced by the Ministry of Environment on the 6th, waste batteries were excluded because of their high raw material value and difficult supply and demand.

An official in the renewable energy industry said, “The reason for the high price of electric vehicles is the battery, which accounts for half of the cost, and the high price makes it difficult to supply and demand.” The advantage is that the price is also low,” he said.

Electric vehicles exploding in demand… 80,000 used batteries are poured out after 10 years

The possibility of the business was opened when the waste battery reuse project, which was selected as a regulatory sandbox, passed the approval of special cases for demonstration. The Sandbox Support Center of the Korea Chamber of Commerce and Industry and the Ministry of Trade, Industry and Energy decided on a special case for demonstrating electric vehicle battery recycling technology at the’Industry Convergence Sandbox Deliberation Committee’ held in October last year. It was also valid that the’proposal of partial amendment of the law on the recycling of electricity, electronic products and automobiles’ passed the plenary session of the National Assembly.

The market outlook is also very bright. First of all, the electric vehicle market is growing rapidly. Market research firm SNE Research predicts that demand for electric vehicles will continue to grow at an annual average of 19%, accounting for 30% of the automobile market in 2030, 10 years later. Report Linker, another market research firm, predicts that the battery recycling market will grow by an annual average of 18.3% by 2030.

The generation of used electric vehicle batteries is expected to increase sharply after next year. With the promotion of the Green New Deal and the ‘2050 Carbon Neutral’, the supply of eco-friendly vehicles is revitalized, and the accumulated number of electric vehicles in Korea will increase to 1.13 million in 2025 and 3 million in 2030. The Korea Energy Economics Institute analyzed that “the number of used electric vehicle batteries from 4,700 last year will increase to 80,000 by 2030.”

The ESS market, which is a consumer, is also growing. According to Bloomberg New Energy Finance (BNEF), the ESS market from 3 gigawatt hours (GWh) in 2017 is expected to grow by about 128 times to 379 GWh in 2040. This is on the premise that the share of renewable energy generation will increase to 40% by 2040.

Related Articles

Hyundai Motor Group starts electric vehicle battery reuse ESS demonstration business

LG, voluntarily recalling ESS in the US…why not in Korea?

Hanwha Solutions reorganizes solar power business… Established hydrogen technology research center

East-West Power, localization of key parts for large-scale wind turbines

In addition to KHNP, Hyundai Motor Company is collaborating with battery and renewable energy industries such as Power Logics, OCI, and Hanwha Q Cells. Power Logics was in charge of producing ESS that recycles Hyundai Motor Company’s waste batteries. OCI is comparing the performance with new batteries by constructing an ESS using Hyundai Motor Company’s waste batteries, and Hanwha Q Cells also began joint development with Hyundai Motor Company based on waste batteries.

An official of the Hyundai Motor Group said, “We will be able to maximize the stable supply and utilization efficiency of highly volatile renewable energy such as solar heat, hydropower, wind power, tidal power, and geothermal heat, as well as improving the eco-friendliness of batteries recovered from electric vehicles.” The data collected and analyzed through this will help to elaborate domestic licensing and licensing regulations,” he predicted.