Input 2021.02.12 07:00

Challenge the global cultural property restoration market dominated by Japanese paper “washi”

Washi, UNESCO listed… Korean paper is not listed, the difference in international reputation

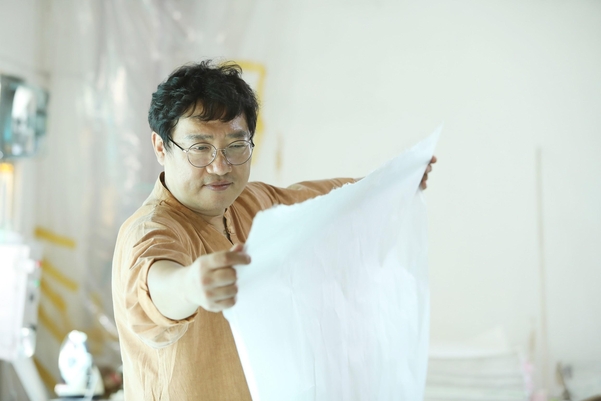

Choi Seong-il (54), CEO of Seongil Hanji in Jeonju, Jeonbuk said, “Hanji using paper mulberry material has a high dimensional stability (a ratio that decreases less during processing) because the fiber tissues overlap horizontally and vertically.

The two types of Korean paper made by CEO Choi were certified as preservation and restoration paper by the Italian National Institute of Ancient Documents and Book Pathology (ICPAL) last August. ICPAL is the world’s most authoritative paper restoration organization and has been reviewed for 5 months. Restoring papers such as paintings and documents is a method in which pieces of Korean paper are pasted on the back of cracked or torn paper, and then the front is painted over or supplemented.

Hanji entered the cultural property restoration market dominated by Washi as a latecomer. Many foreign countries do not know the merits of Korean paper, so they requested certification from ICPAL to inform the quality. He said, “The unique characteristics of Korean paper were preserved, but the addition of a process such as lump fibers was added to complement the process,” he said. “If the corona crisis subsides, there will be more opportunities to inform overseas.”

Washi was registered as a UNESCO Intangible Cultural Heritage in 2014, but Hanji must win 26 cases including Taekwondo and Korean food in order to become a candidate for registration in 2026. If it falls, you have to keep preparing every two years.

CEO Choi said, “Korea has 16 UNESCO World Records, the fourth largest number in the world, including the Annals of the Joseon Dynasty and the Seungjeongwon Diary, and 13 cases are related to Hanji. It is ironic that Hanji is not registered in the I hope to be listed in a hurry to increase added value,” he said.

He has been helping his deceased father since he was a child and then naturally started his family business. One of the four Hanjijangs designated by Jeonju in 2017 makes paper for 35 years. Last year, the Ministry of SMEs and Startups was recognized for his craftsmanship and proficiency and was selected as a ‘100-year-old man’. The workshop is run by five people, including his wife, younger sister, son and one employee.

Most of the products are supplied to Insa-dong and some are exported to Japan, France, Australia and Taiwan. CEO Choi said, “We export 60 to 70 million won worth annually to Nagoya and Tokyo,” he said. “Quality satisfaction is high, but because of the traditional method, it is difficult to handle the quantity even if overseas orders increase.” It is said that it is difficult to increase the production quantity because it is difficult to find a craftsman who can withstand the skill period that takes 5 to 10 years.

CEO Choi said that it is a pity that the chances of seeing Korean paper in Korea are decreasing. He said, “It is an environment that makes it difficult to feel the charm of Korean paper because calligraphy academies are almost disappeared and hand-written letters are hardly used,” he said.

He said, “In order for Korean paper to become global, it is difficult to ask for an understanding of the characteristics of Korean paper,” he said. He added, “In the future, I want to cultivate handmade people and organize the process of making Korean paper that the five senses remember, and publish the know-how in a book.”