“Reduction of high frequency noise and minimization of component mounting area”

The thinnest thickness among 1209 size 3-terminal MLCCs

Samsung Electro-Mechanics announced on the 20th that it has developed a 0.65mm thickness 3-terminal multilayer ceramic capacitor (MLCC) and is supplying it to global smartphone makers. It seems that a new product has been delivered to the Galaxy S21 series that Samsung Electronics launched last week.

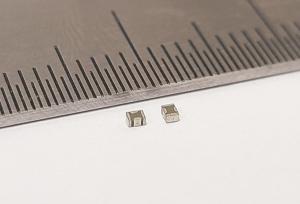

The 3-terminal MLCC developed this time by Samsung Electro-Mechanics implemented a 0.65mm thickness in 1209 dimensions (1.2mmX0.9mm). Samsung Electro-Mechanics explained that the thickness of the commercialized 1209-size MLCC is the thinnest in the industry.

The terminal is a part that allows current to flow through the MLCC by bonding to the circuit. The 3-terminal MLCC has an additional terminal between the two terminals. Current flows through the terminal at one end and the terminal in the middle to realize the characteristics. In this structure, the path through which the current flows is shortened. The 3 terminal has a shortcut for the current to travel. General MLCCs have two terminals at both ends, so current flows through both ends to realize the characteristics.

The advantage of this product is that the degree of freedom in smartphone design has increased. It is 18% thinner than the existing 1209 size MLCC product thickness of 0.8mm, so product design is free. Recently, the demand for small and thin parts has increased as the number of parts to be mounted on smartphones has increased due to 5G mobile communication and multi-cameras.

The 3-terminal MLCC can efficiently remove high-frequency noise generated from the power stage of the application processor (AP) of 5G smartphones. One 3-terminal MLCC can replace three or four general MLCCs, which is advantageous in securing space for mounting parts. Samsung Electro-Mechanics explained that it has succeeded in developing a 3-terminal MLCC by applying its own thin-layer molding and ultra-precision lamination technology.

Samsung Electro-Mechanics claims that MLCC miniaturization and stacking technology is the best in the industry. The company plans to expand its product lineup and market share by developing raw materials and applying the next-generation facility construction method.

Samsung Electro-Mechanics Vice President Kim Doo-young said, “With the commercialization of 5G mobile communications and automotive electrification, the demand for ultra-small, high-performance, high-reliability MLCCs is increasing.” Said.

Copyright © The Elec, the electronic component specialty media Unauthorized reproduction and redistribution prohibited