Input 2021.03.19 14:00

According to related industries on the 19th, LG Energy Solutions Samsung SDI (006400), SK innovation (096770)Korea’s major battery companies are concentrating on the development of next-generation batteries, including all-solid-state batteries.

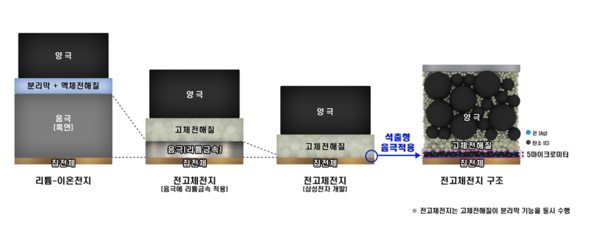

All-solid-state batteries are batteries made of solid liquid electrolytes in lithium-ion batteries currently used in electric vehicles. Structural safety is higher than that of lithium-ion batteries, so there is less risk of impact and damage. It also has the advantage of increasing the mileage of electric vehicles as it can increase power and energy density.

Among domestic companies, Samsung is the one that takes the lead in developing all-solid-state batteries. Samsung SDI, along with its own development project, Samsung Electronics (005930)It is jointly developing all-solid-state battery technology in collaboration with the Korea Institute of Technology and Japan Research Institute.

Dendrite is a tree branch-shaped crystal that appears when lithium, which moves from the positive electrode to the negative electrode, accumulates on the surface of the negative electrode when charging a battery. These crystals damage the separator of the battery, reducing the life and safety. In addition, it can cause fire or explosion by tearing the separator.

The Korea Advanced Institute of Technology applied the’precipitation type lithium cathode technology’ that solves the dent light problem to an all-solid-state battery for the first time in the world. It has secured the original technology to solve the dendrite, which is the biggest challenge of all-solid-state batteries. Samsung Electronics’ all-solid-state battery is capable of driving 800km on a single charge and recharging more than 1000 times. The target period for commercialization is set in 2027.

“This research is a key source technology for innovatively increasing the mileage of electric vehicles,” said Lim Dong-min, a master at Samsung Electronics Advanced Institute of Technology.

SK Innovation is also developing a lithium metal type all-solid battery. The all-solid-state battery that SK Innovation is researching is characterized by its ability to significantly increase the energy density to 1000Wh/L (watt-hour/liter) or more. Currently, 800Wh/L is considered the limit for lithium-ion batteries. As the energy density increases, the battery volume decreases, so more batteries can be added to the electric vehicle to increase the mileage. To this end, the Nobel Prize in Chemistry in 2019, John Goodenough, is working with a professor at the University of Texas to develop a battery. Professor Goodenough is evaluated as a person who opened the era of lithium-ion batteries. It is known that SK Innovation will also develop dendrite resolution technology with Professor Goodenough.

In the industry, it is pointed out that research on all-solid-state batteries by domestic companies is a bit late compared to competitors. Toyota and Panasonic of Japan are developing all-solid-state batteries with the aim of mass production in 2025. Initially, during the 2020 Tokyo Olympics, an electric vehicle with an all-solid battery was expected to be introduced.

Volkswagen’s battery partners, North Volt and Quantumscape, are also targeting mass production of solid-state batteries by 2025. Volkswagen has made plans to become the first electric vehicle maker to use all-solid batteries. According to the European Intellectual Property Office (EPO), Japan ranked first with 54% of international patents for all-solid-state batteries, followed by the United States (18%) and Korea (12%).

An industry insider said, “For the development of next-generation batteries, public-private partnerships must make large-scale investments and devote all efforts to technology development.” .