World semiconductor companies are stepping up to raise the price of semiconductors for vehicles one after another. Automotive semiconductors are currently in short supply worldwide, and supply is unlikely to increase for a while, which will increase the burden on automakers.

○ Semiconductor company “Up to 20% increase in price”

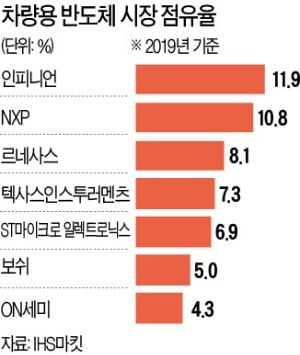

According to the Nippon Geizai Newspaper on the 23rd, NXP, the Netherlands NXP, the second and third largest company in the global automotive semiconductor market, and Renesas of Japan, and the fifth largest company, Swiss STMicroelectronics, have entered into negotiations with trading companies to raise product prices. According to market researcher IHS Markit, these three companies accounted for more than 25% of the global automotive semiconductor market in 2019.

Nihon Geizai cited multiple sources and reported that NXP and ST Micro had requested a 10-20% increase in semiconductor prices. Renesas asked the trading company to increase the price of semiconductors for vehicles, servers, and industrial use, including microcontroller units (MCUs) that control each function of the vehicle. It is known that Toyota Motor Company’s subsidiary Denso and parts maker Continental, which supplies products to Volkswagen, Germany, have received such notification.

Nihon Keizai said, “The automotive semiconductor companies are in a position to raise the price of semiconductors due to the sharp increase in the cost of consignment production (foundry).” NXP and Renesas are mostly fabless (semiconductor design companies) that do not have production facilities. They entrust the production to Taiwan TSMC, UMC, and Samsung Electronics. However, since last year, foundry companies have focused on producing 5G (5G) communication devices or semiconductors for PCs, smartphones and servers instead of semiconductors for vehicles. Since the Corona 19 crisis, the demand for automobiles has decreased significantly, and the demand for various electronic devices required for working from home has exploded.

The reason is that automotive semiconductors are not easy to mass-produce in a short period of time compared to other semiconductors and have a small margin. Although demand for automobiles has recently recovered, foundry companies are known to have subordinated automotive semiconductors.

○ Semiconductor shortage phenomenon

As the supply of automotive semiconductors decreases, global automakers are disrupting production. On the 18th, Audi postponed production of high-end models and left 10,000 employees on a short break. Audi aims to keep the production decline below 10,000 units in the first quarter of this year. The Volkswagen Group, which is affiliated with the Audi brand, predicts that the group’s total car production will decrease by about 100,000 units in the first quarter of this year.

Ford has closed its Louisville Sports Utility Vehicle (SUV) plant in Kentucky, USA, and the Saarlouis plant in Germany will be closed by the 19th of next month. FiatChrysler (FCA) has temporarily suspended operations at its Ontario plant in Canada. The Jeep brand’s Mexican plant restarts will also be delayed. Toyota announced plans to cut production at its plant in Texas, USA. Nissan will cut its note production this month.

Experts expect the shortage of vehicle semiconductors to continue for the time being. This is because the global foundry industry cannot increase the production of semiconductors for vehicles in a short period of time, and it is difficult for automobile companies to maintain multiple suppliers to meet the required volume.

According to Nihon Geizai, a 10% increase in automotive semiconductor prices will increase automobile production costs by 0.18% and reduce operating profit by 1%.

Reporter Sun Han-gyeol [email protected]

Ⓒ Hankyung.com prohibits unauthorized reproduction and redistribution