Enter 2021.01.27 12:00

The old industry has the highest penetration of robots… “After Corona, the spread of robots will increase”

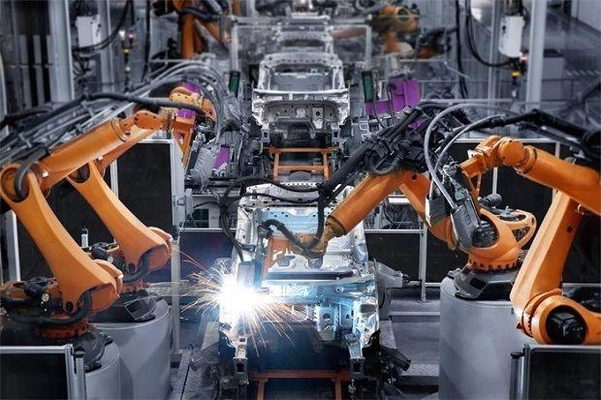

In the 2010s, the number of industrial robots in Korea increased by about eight times, showing the highest degree of use of robots in the automobile industry. It was investigated that the spread of robots has an effect on the rate of increase in jobs and wages while causing substitution effects. The Bank of Korea has published a research result that the increase in the number of workers decreases by 0.1 percentage points (p) if one robot per 1,000 workers in the industry increases.

According to the monthly survey statistics published by the BOK on the 27th, the number of industrial robots operated by Korean industrial robots increased by about 8 times from 38,000 in 2000 to 300,000 in 2018. In terms of the number of units sold, it increased by about 7 times from 0.5 million units to 380,000 units over the same period.

This is because, in the case of Korea, in terms of industrial structure, industries with large incentives to use robots occupy a high proportion of production. Based on GDP in 2019, the proportion of electricity/electronics (32.2%), chemicals (15.4%), transportation equipment (11.0%), and mechanical equipment (9.1%) in the manufacturing industry is high. This industry has relatively high labor compensation costs, and some industries have high incentives to use robots due to their high work simplicity.

As a result of surveying the degree of robot penetration by industry, robot penetration has progressed the fastest in the automotive industry since 2010. The degree of penetration of robots is a concept devised separately by the BOK as the gap between the increase in the supply of robots per 1000 people and the increase in the supply of robots per 1000 people, which is assumed to have grown by the value-added growth rate of the industry.

The degree of penetration of robots in the automobile industry increased by 6.3 units per year on average from 2010 to 18, while the food and textile industries only rose by 0.05 and 0.001 units, respectively.

It was found that the spread of such robots reduced the rate of increase in the number of industrial workers through the substitution effect. It is estimated that as the degree of penetration of robots increases by 1 unit, the increase rate of the number of workers in the industry decreases by about 0.11 to 0.23 percentage points (p). This means that if the number of robots per 1000 workers increases without any change in added value, the increase rate of the number of workers in the industry decreases by 0.1%p.

The use of robots caused similar substitution effects for real wages. It is estimated that if the robot penetration rate increases by 1 unit, the real wage increase rate of the industry will drop 0.27~0.29%p.

A BOK official said, “As the digital transformation accelerates after Corona 19, the supply of robots will proceed more rapidly.” did.