Introduced sequentially over the next 5 years

From the second half of the year, Icheon M16 plant

Use it for mass production of the latest DRAM

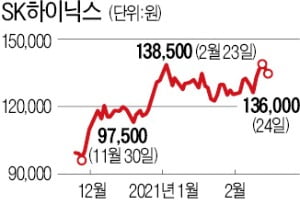

SK Hynix will invest 480 trillion won over the next five years to bring in about 20 EUV (extreme ultraviolet) exposure equipment. It plans to improve semiconductor performance and process yield (proportion of good products among all products) by introducing EUV equipment to mass production of its flagship DRAM product.

On the 24th, SK Hynix announced on the 24th that “We have signed a contract with ASML to purchase EUV exposure equipment by investing 4,754.9 billion won over the next five years.” The price is paid every time equipment comes in. The exact number of orders was not disclosed. Considering the EUV equipment price and installation costs, which are around 200 billion won per unit, it is estimated to be around 20s.

EUV equipment is the only production in the world by Dutch equipment company ASML. It is used to engrave circuits on wafers, which are semiconductor disks. The wavelength of the light source that engraves the circuit is thinner by a factor of 14 compared to conventional equipment. That way, you can draw the circuit in detail. Another advantage is that the’multi-patterning’ process that repeats the process of engraving the circuit is reduced. It is evaluated that it can improve semiconductor performance and yield and shorten product development period.

EUV equipment is mainly used for ultra-fine processes with a line width of 7 nm or less (nanometer, 1 nm = 1 billionth of a meter) of Samsung Electronics’ Foundry Division and Taiwan TSMC. Last year, Samsung Electronics’ memory division used EUV equipment to mass-produce DRAM (1st generation 10nm product) for the first time in the industry. This year, it plans to mass-produce the 4th generation 10nm DRAM on the EUV line. SK Hynix will also use EUV equipment for mass production of 4th generation 10nm DRAM from the second half of this year at the M16 plant in Icheon, Gyeonggi, which was completed on the 1st of this month.

It is predicted that major semiconductor companies’ competition for securing EUV equipment will become more intense. There are around 40 EUV equipment that ASML can manufacture in one year, and the supply cannot keep up with demand. It is known that TSMC has secured about 50 EUV equipment by the end of last year and Samsung Electronics’ 10-20 units.

An industry official explained, “Without EUV equipment, it is impossible to expand the production of ultra-fine processes.”

Reporter Hwang Jung-soo/Lee Soo-bin [email protected]

Ⓒ Hankyung.com prohibits unauthorized reproduction and redistribution