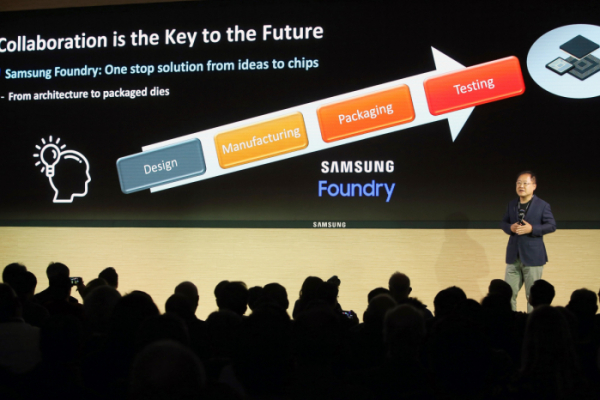

▲ On the 17th (local time), Jaehong Park, Vice President of Samsung Electronics’ Foundry Division, is giving a keynote speech at the’SAFE Forum’ held to strengthen the foundry ecosystem at Samsung Electronics’ DSA office in Silicon Valley, USA. (Photo courtesy = Samsung Electronics)

Samsung Electronics is expanding outsourcing cooperation with small and medium-sized domestic partners in order to respond to the influx of system semiconductor orders. As system semiconductors are also in short supply due to increased demand from downstream industries, it is interpreted that they have started to strengthen the domestic system semiconductor ecosystem.

According to the semiconductor industry on the 23rd, as the demand for system semiconductors increased from the end of last year, Samsung Electronics began to increase the system semiconductor design service assignments entrusted to domestic SMEs.

Samsung Electronics has been entrusting part of semiconductor design to companies registered as partners of SAFE (Samsung Foundry Ecosystem). Until now, small and medium-sized companies have participated in Samsung Electronics’ semiconductor design projects, and Samsung Electronics has directly mass-produced them.

Recently, as Samsung Electronics’ limited design manpower has become more difficult to handle orders, it is understood that the number of products entrusted to outside design has increased, focusing on general-purpose products that are relatively easy to technical difficulties except for main products.

An official in the semiconductor industry said, “Samsung Electronics has not only given tasks to its partners, but has also begun to actively encourage partners’ own sales. As the number of design service tasks in the semiconductor market increases, the industry is also improving.”

Most of Samsung Electronics’ business partners turn 50~60% of their own semiconductor design manpower to handle Samsung Electronics tasks, create a cash flow, and increase profitability with the remaining manpower. Bidding) Challenge the solution. As semiconductors have recently entered an extremely booming phase, Samsung Electronics is encouraging suppliers to expand turnkey solutions.

Depending on the timing of receiving orders for Samsung Electronics’ semiconductor design projects, partners sometimes have a gap of 2-3 months, and to eliminate this gap, it is known that small and medium-sized semiconductor companies form an alliance to win orders directly.

Samsung Electronics’ move to encourage partners appears to be a strategic measure amid concerns over prolonged semiconductor shortages. The supply and demand shortage of semiconductors is spreading to all industries such as smartphones and TVs following automobiles. In addition to memory semiconductors, demand surged in overall system semiconductors such as AP (mobile application), CIS (image sensor), and DDI (display drive chip), which are the brains of smartphones.

In recent years, as a result of the cold wave that occurred in the US, global semiconductor factories including Samsung Electronics have been shutting down, and the supply-demand crisis is worsening. Market research firm TrendForce analyzed that, in relation to the situation in which Samsung Electronics’ Austin semiconductor plant in Texas, USA was stopped, “there was a loss equivalent to about 1-2% of the global 12-inch factory production volume due to this cold wave.”

An industry insider said, “In order for Korea to continue to take the lead in the face of the semiconductor supercycle, a more strengthened domestic semiconductor ecosystem is needed.” “Samsung Electronics, in order to respond to the global market in a short time, requires a lot of money and time for production expansion and expansion. It is expected that the semiconductor ecosystem with small and medium-sized business partners centered on and SK Hynix will become more solid.”

Samsung Electronics announced’Semiconductor Vision 2030′ in 2019, which aims to achieve the world’s number one system semiconductor by investing 133 trillion won by 2030, and has been strengthening cooperation with small and medium-sized semiconductor companies in Korea.

Samsung Electronics is also actively supporting the production of small-scale products by small and medium-sized fabless companies in Korea by easing standards for consignment production of semiconductors. It is expanded to 3 times. It is also expanding outsourcing cooperation with domestic design house companies.

Samsung Electronics Vice Chairman Lee Jae-yong attended a ceremony for bringing in foundry production facilities at Pyeongtaek Plant 2 as his first management step in January of this year, and then discussed ways to foster domestic semiconductor ecosystems and promote mutual cooperation with representatives of partner companies.

At the time, Vice Chairman Lee said, “Let’s take a leap forward as a new Samsung in the new year. Together, we can open up our future. Samsung Electronics and its partners, academics, and research institutes cooperate to create a healthy ecosystem and create a myth in system semiconductors.”