With governments and automakers urgently requesting’expanding the supply of semiconductors’, foundry companies that make semiconductors for automobiles (semiconductor contract manufacturing) are expanding. It is known that some production lines are being considered for conversion to’vehicle semiconductors’.

According to a foreign press on the 4th, Taiwanese foundry company VIS decided to set a facility investment (CAPEX) of 5.1 billion Taiwan dollars (about 20.4 billion won) this year. This is an increase of 44.1% compared to last year’s investment amount (3.54 billion Taiwan dollars). VIS is the world’s 6th to 7th largest company that produces semiconductors mainly from 8-inch (200mm) diameter wafers (semiconductor disks) receiving orders from customers. It is analyzed that the scale of facility investment was increased compared to the previous year due to the flood of automotive semiconductor orders.

In Korea, Key Foundry plans to expand capacity sooner or later. Key Foundry is an 8-inch foundry that was separated from Magna Chip and sold to a private equity fund (PEF) in March last year. Manufactures by ordering rear detection sensors. An official from Keyfoundry explained, “By this time, production can increase by about 10% from the second half of the year.”

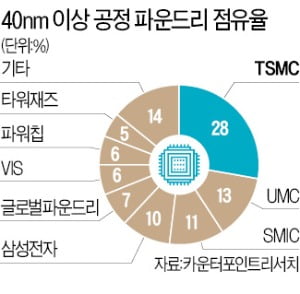

It is known that Taiwan’s TSMC and UMC are considering expanding their automotive semiconductor production lines or turning some of their lines for vehicles. This is because the governments of the United States, Germany, and Japan have requested Taiwan to increase the supply of semiconductors for vehicles. There is also a prospect that the’shortage of automobile semiconductors’ will not be resolved in a short period of time. Even if it is expanded now, it will take more than 6 months to produce. In response to such a move in the semiconductor industry, companies that ordered semiconductors for information technology (IT) products from foundries are concerned, “Isn’t our quantity decreasing?”

For latecomers who have entered the automotive semiconductor market such as Samsung Electronics, it is also evaluated that the semiconductor shortage phenomenon is rather’positive’. Samsung Electronics supplied the AP’Exynos Auto’, which serves as the brain of automobiles, to Audi in Germany, and is also developing and producing automotive DRAM. Recently, to strengthen the automotive semiconductor business, it has also started hiring experienced professionals.

Reporter Hwang Jeong-soo [email protected]

Ⓒ Hankyung.com prohibits unauthorized reproduction and redistribution